Production Director Zdeňka Vaverová: The customer always comes first

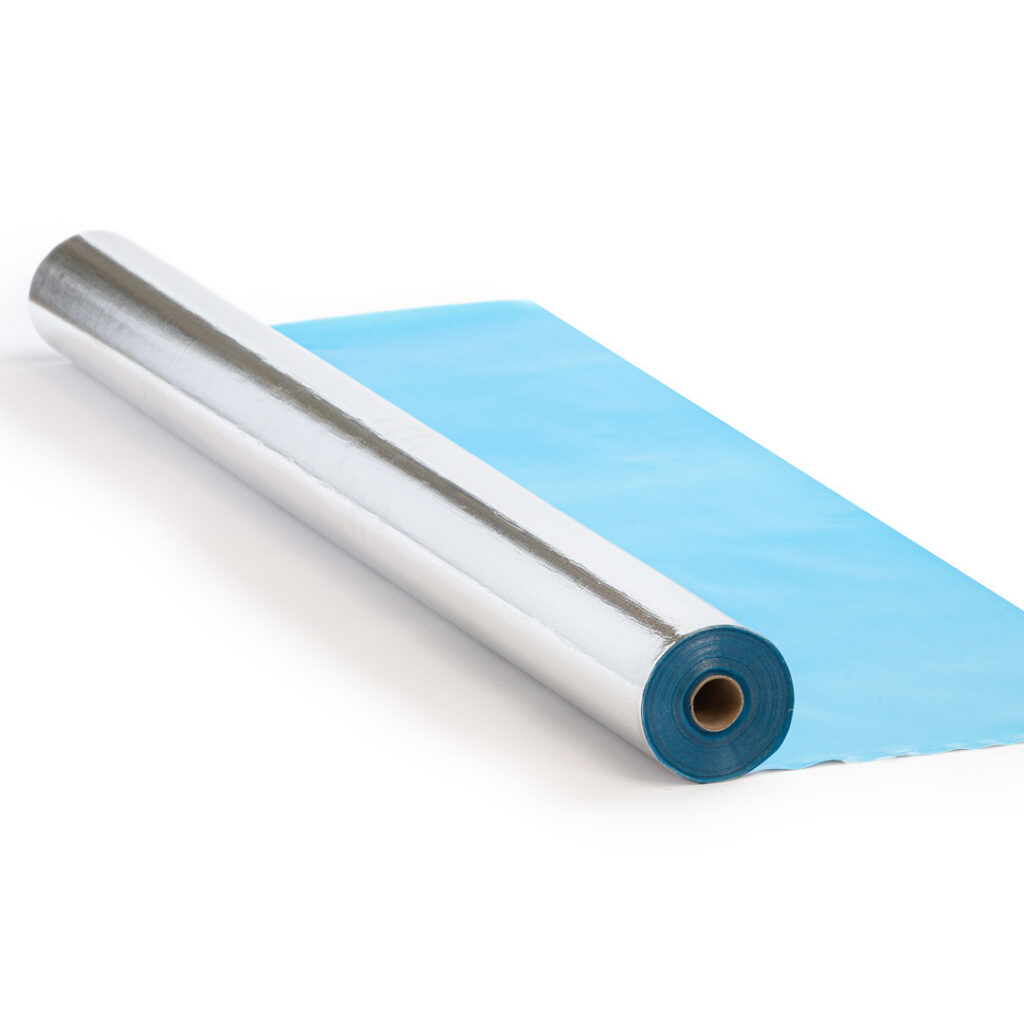

One of the most important areas of our production is the SVITAPFOL production programme, which is located in our plant in Svitavy. In this segment we specialize in the production of laminated and under-roof films, textile laminates and fully recyclable PET strapping. The production department is headed by Ing. Zdeňka Vaverová, who has been part of our company for 13 years as Production Director and Chief Technologist. In an interview she explained how she perceives the changes and development of the production programme and where the Svitav plant is heading.

What do you enjoy about being a technologist and how do you perceive your position in the management?

This role allows me to actively influence the product from its inception. The work of a technologist is exceptionally varied, consisting of communicating with clients about their ideas and requirements, as well as negotiating with suppliers to secure the necessary raw materials. Equally important is the cooperation with production managers and machine operators to find together the optimal ways of implementing production.

From my management position, I try to be in constant contact with the shop floor staff, who I consider to be great experts and whose work and experience are invaluable and provide the necessary basis for the further development and prosperity of the company. Knowing that I can contribute to their development and efficiency is, I admit, very pleasing.

In recent years, there has been increasing discussion about ecology and its impact on production processes. How does SVITAP company reflect these ecological requirements and strive to be an environmentally responsible company?

The company aims to minimise waste through efficient and well-planned production. For waste, we try to find opportunities for its further processing and recovery. Up to 90% of the waste produced finds its way to customers who give it a new life. Another step in the company's environmental strategy is the use of recycled materials and the constant search for new ways to improve. SVITAP company also seeks to support domestic producers and thus reduce emissions associated with the transport of raw materials. The company continuously monitors legislative standards and requirements, which is made easier by customer enquiries, as different countries have different standards that must be respected in production.

How do you find and develop new business opportunities?

During my time at SVITAP company I have witnessed an unprecedented expansion of competition, which can be attributed to better availability and speed of transportation enabling import of goods from long distances at significantly lower prices. In this context, the efficient and flexible functioning of our sales and marketing departments is of paramount importance. Our main goal is to meet our customers' expectations to the smallest detail, which is a strong incentive for them to establish or deepen their cooperation with us. Our joint efforts are aimed at creating a convincing presentation of our services, targeted deployment of advertising campaigns with the intention of expanding and consolidating the ranks of satisfied customers.

Is it possible to incorporate customer requirements and ideas into the product development and production process?

For us it is essential to get feedback from customers who actually use our products. We are dedicated to the continuous improvement of our offer and are ready to develop new solutions if necessary. The customer should always come first and that's why we try to meet their requirements in the best possible way. A quick response is key to show that we value their satisfaction and strive to resolve requests without delay. Delays could lead to the customer choosing our competitors.

Where would you like to develop?

We all are striving to create a stable and modern company that bases its success on the satisfaction of both customers and employees. We simply want to be a company where people like to work and whose satisfaction is reflected in the work done. We have experienced employees who have been with the company for over 30 years, but also young, skilled people who are not afraid of work and bring fresh wind and new ideas to the team at all levels of the company. Three things are important for a company to develop and without them it cannot - quality products, satisfied customers and satisfied employees.

What are the plans for the coming year?

We have managed to overcome an unfavourable period when not only raw material prices but also energy prices rose to considerable heights, which had a negative impact on the results for 2022. In response to this situation, a number of key measures have been taken, including optimising production facilities, regulating heating, streamlining production planning, improving the quality of production and thus reducing the volume of waste generated. Thanks to these measures, production has been stabilised and satisfactory results have already been achieved in 2023.

In the coming months we will focus on actively seeking further opportunities for cost savings while maintaining high quality production. In addition, our efforts will be directed towards expanding our customer portfolio and investing in new product development to strengthen our competitiveness in the market. If we are successful in meeting these objectives, it will open up space for considering other production opportunities.

See our websites:

www.svitapfol.cz

www.petpasek.cz/en/

www.textilni-laminace.cz/en/